Thermoselect - SSBI is your one-stop source for all Municipal Solid Waste Management Solution. The system is considered as an Environment Friendly Waste management System for municipal Solid Waste. The system has been designed to reduce cost of the MSW, integrated with Gasification System is for Zero waste solution. The process having following process which reduce waste with no hazards

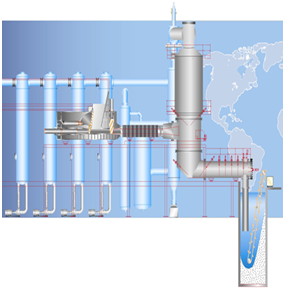

1) Waste press/Compactor

2) Degassing & Drying channel

3) High temperature reactor/Gasifier

4)Scrubber.

Synthesis Gas can be used for Production of Hydrogen, Methanol, Ammonia, Power generation. If half of the syngas is used for hydrogen production and the other half is used to produce electricity and steam, the SSBI-Thermoselect plant including the hydrogen production should be able to operate without use of external energy.

A good neighbour, no odors, gas emission or vectors. Bales can be held in long term storage.

- Outside storage and efficient transportation.

- No Land fill compactor, no daily cover, free draining bales minimize leachate contamination, rapid bale fill closure.

- High density waste maximize waste placement and extend landfill operating life.

- Zero waste Solution by using Microwave Induced Gasification.

Thermoselect-SSBI is high temperature gasification is a recycling technology applied to residual waste. The only such technology in the world. It transforms waste that are considered non recyclable into energy and by-product that are reused into industrial applications. It is a true form of recycling; 100% of the treated waste is recycled into usable by-products. Technology accepts not only household waste, but also most types of commercial and industrial wastes, hazardous wastes. This is one of the most convenient solutions under �Swachh Bharat Mission�.

Municipal solid waste, Industrial waste, Hazardous waste, plastic waste, Bio waste, RDF, Waste Mixtures, Tires, Electronics waste.

All type of Municipal Solid Waste and Industrial waste.

600 TPD I 1000 TPD I 2000 TPD and 5000 TPD and more.

- Is not an incineration technology.

- 100% of the waste becomes useful recycled products like synthesis gas, chemicals, water, salts, metals, minerals etc.

- No ash is generated - No landfills required.

- Comprehensive solution - Processes all forms of waste.

- Has no process water discharges.

- Air emissions are 90% lower than permitted by government.

- Requires only 10 acres of land to process up to 500,000 tons of waste per year for 30 years.

Flexible and modular which consume less space but still its depends upon the actual site.

Globally implemented in Asia, Europe.

25-30 years.

- MSW at the rate of 150 to 5000 tons per day will be received at the processing site. Operating equipment will be sized according to the MSW volume and may include multiple processing lines in order to accommodate larger daily MSW volumes.

- It will segregated and shredded according waste

- Shredded MSW will feed to the Thermoselect Gasifier. The waste is then compacted to take out any residual air in the waste stream.

- The waste then goes through a chemical process occurring into the horizontal degasifying tunnel, at 600 degrees C and airless condition.

- This first part of the process treats the organic portion of the waste only, and they are transformed into a blend of gases, called syngas.

- This first part of the process treats the organic portion of the waste only, and they are transformed into a blend of gases, called syngas.

Chiba, Japan.

330 TPD. MSW, Industrial waste and sludge .

Recycles MSW and IW waste 100% into commercially useful products without landfill.

THERMOSELECT- SSBI- Advanced High Temperature Recycling Process .

Produces energy rich synthesis gas used to

- Generate electricity.

- Manufacture alternative fuel.

- Recycles waste 100% into commercially useful products

- No ash is produced; no landfill is required No ash is produced; no landfill is required.

- Comprehensive solution - processes all forms of waste.

- Can process waste between 3,500 to 10,000 Btu/lb (HHV).

- Solids, sludges, liquids.

- Producing a chemical product from syngas like ammonia, hydrogen, methanol, diesel, gasoline, etc.

- 100% recycling of waste to usable products.

- No ash is generated - No landfills required.

- Zero emission from waste treatment.